Wet blasting

Revolutionizing surface rinishing with wet blasting technology

Why shoose wet blasting?

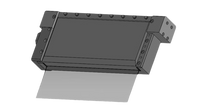

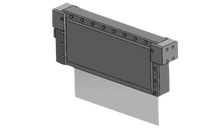

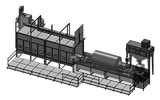

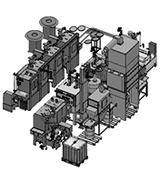

Technology in Action: WA 5000 Brilliant

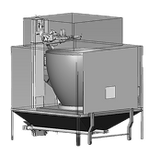

WA 5000: The Pinnacle of Wet Blasting Innovation

Our flagship machine, the WA 5000 BRILLIANT, is the most advanced wet blasting solution in the market. Designed for 24/7 operation, this fully automated system integrates multiple processes in a single unit for maximum efficiency and reliability.

01

Automatic tray loading onto the conveyor system

02

Eight strategically placed blasting pistols or one flat / knife nozzle for thorough coverage.

03

Nicolis flat-blasting nozzle ensures even surface treatment.

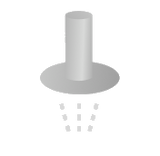

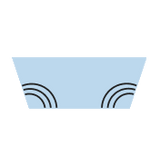

Patented technology for your success: the flat jet knife-like nozzle

6 advantages of using a flat jet or knife-like wet blasting nozzle compared to round nozzles:

- Wider Coverage Area: Flat jet nozzles create a broader, fan-shaped blast pattern, making them ideal for covering larger surface areas quickly and efficiently.

- Precision Cleaning: The knife-like blast stream allows for precise control, making it suitable for detailed cleaning, especially on flat or slightly curved surfaces.

- Uniform Abrasion: The even distribution of abrasive material in the flat jet ensures consistent surface treatment, reducing the risk of uneven wear or damage.

- Reduced Media Consumption: With focused energy across a larger area, flat jet nozzles can achieve desired results with less abrasive material compared to round nozzles.

- Versatility: These nozzles are particularly effective for cleaning and finishing applications, such as preparing surfaces for coatings or removing thin layers of rust and paint.

- Minimized Overlap: The elongated spray pattern reduces the need for overlapping passes, saving time and enhancing productivity.

04

Coarse cleaning of workpieces.

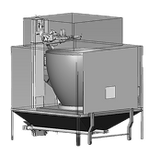

05

Tray immersion in the ultrasonic cleaning bath.

06

Fine cleaning phase 1.

07

Fine cleaning phase 2.

08

Workpieces are dried and prepared for immediate packaging.

09

Automatic tray unloading.

Applications of Wet Blasting

Versatile Applications for Every Industry

Adaptable to diverse needs, from precision cleaning to material preparation.

Ironing

Achieve smoother surfaces with precision surface ironing (removal of droplets).

Edge honing

High precions and repeatble edge honing for your tools.

Stripping

Efficient removal of coatings and material layers.

Deburring

Remove sharp edges for safer and more functional parts.

Cleaning

Deliver spotless surfaces for subsequent processes.

Shot Peening

Enhance durability and resistance of materials.

Industries we serve

Trusted across industries

Nicolis wet blasting systems are engineered to meet the rigorous demands of various industries, including:

-

Medical technology

Precision cleaning for surgical tools and implants.

-

Aerospace

Durable surface treatments for turbine blades and structural components.

-

Tooling

Reliable finishing for carbide tools and inserts.

-

Surface engineering

High-quality surface preparation for advanced coatings.

-

Automotive and gear technology

Efficient deburring and component finishing.

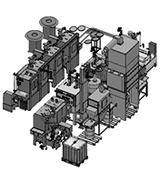

Other machine types

Solutions for any need

Nicolis produces an array of different wet blasting systems including:

X-Y coordinates wet blasting system

Roller / cylinder blasting machines

Planetary / index table wet blasting machines

Infinite band saw blasting, custom specific build

Big parts blasting with robot e.g. rocket / aerospace parts or other.