Dry blasting

Dry Blasting: Precision and Performance Redefined

Why Dry Blasting?

Dry Blasting Technologies

Applications of Dry Blasting

Versatility across industries

Nicolis Technology dry blasting machines excel in diverse applications, from industrial-scale processes to precision treatments.

Material removal (stripping)

Precise removal of coatings, rust, and contaminants.

Surface preparation

Preparation for coatings or adhesion processes.

Edge honing

Honing edges of tools to exact radius desired.

Deburring

Removal of sharp edges to improve functionality and safety.

Polishing

Achieving smooth, finished surfaces for aesthetics and functionality.

Shot Peening

Surface strengthening to increase durability.

Industries We Serve

Driving Excellence Across Industries

Nicolis Technology dry blasting systems are trusted by industries worldwide for their reliability and adaptability.

-

Tooling

Reliable surface treatments for carbide tools and inserts.

-

Aerospace

High-precision applications for turbine blades and aircraft components.

-

Medical Technology

Enhanced surface treatments for implants and instruments.

-

Automotive and Gear Technology

High-performance finishing for gas turbine blades, gears and engine components.

-

Surface Engineering

Specialized treatments for advanced materials.

Case Studies

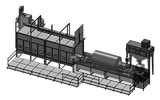

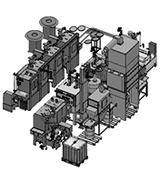

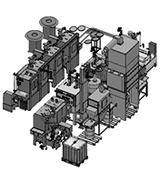

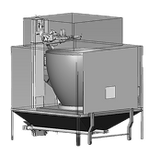

Other Machine Types

Solutions for any need

Nicolis produces an array of different dry blasting systems including:

Inline / continuous dry blasting systems

X-Y coordinates wet blasting system

Roller / cylinder blasting machines

Planetary / index table dry blasting machines

Infinite band saw blasting, custom specific build

Big parts blasting with robot e.g. rocket / aerospace parts or other.