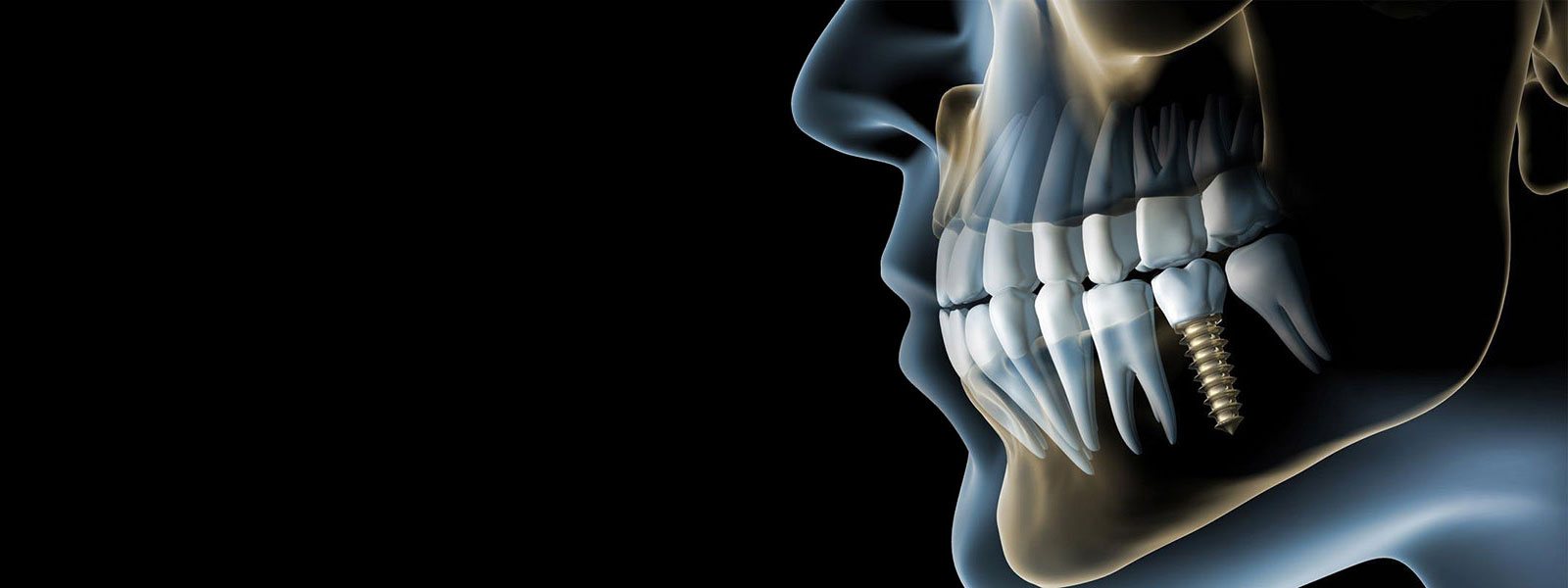

Cutting-edge and high-quality solutions in medical engineering

Optimum adhesion is achieved through the creation of various surface structures (roughness). Through the possibility of simultaneous use of the most different of blasting media and grain sizes, several surface treatments can also be carried out in one machine. Shot peening is the most rational and meaningful process for the creation of internal pressure tensions on the surface. This evens out the tensile stress or reduces it which in turn leads to an appreciable extension of the service life. Shot peening machines for the most various of applications are a core competence of Nicolis Technology and have proven themselves in the market.

Our high-tech solutions:

- 100% process control for perfect blasting results

- Exact dosage and flow control by means of special sensors

- Automatic parameter adjustment (e.g. barcodes, RFID, etc.) possible

- Precise blasting of complex parts through specific nozzle movements

- Automatic loading and unloading of implants

- Full automation enables economical small series

- 100% process reproducibility

- Low-wear blasting guns

- Flexible configuration of the number of satellites and nozzles

- Optimum adhesion is achieved through the creation of varying surface structures (roughness)

- Nicolis Technology makes the simultaneous use and recycling of different blasting media in diverse grain sizes on one machine possible

- The Nicolis Technology wet blasting technology ensures, amongst other things, the highest homogeneity for knee endoprotheses

- Complete recording of all relevant signals and parameters during the blasting process

- Programmable blasting pressure regulation